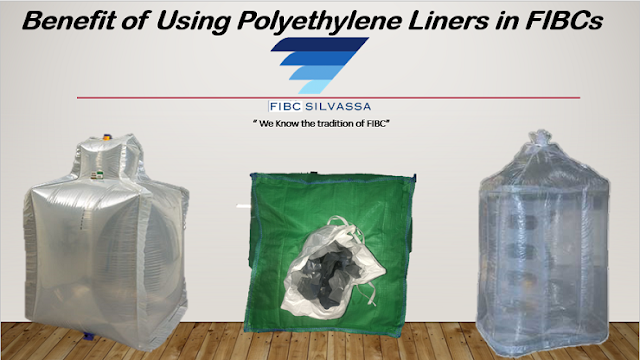

Benefit of Using Polyethylene Liners in FIBCs

Installing polyethylene liners for FIBC is to provide protection to the FIBC bag and to the products inside the bag. there are many other benefits of using FIBCs with liners:

Benefit of Using Polyethylene Liners in FIBCs

- Stop contamination as liners make FIBC bags almost impenetrable

- Stop powdery substances from sifting through FIBCs. In FIBCs individual strands of polypropylene are woven together, and thus, powdery substances are likely to sift through the bag.

- Stop leaks

- Stop dust and moisture from shipping into the bag.

FIBC liners have become vital in the following situations:

- when storing or transporting chemicals, help to keep the product safe and keep the quality of the FIBC bag intact. Certain chemicals can cause fast failure of FIBC bags which are otherwise designed to last multiple-usage.

- When transporting sensitive products Liners are considered crucial when shippers have to transport sensitive consumables such as food and pharma-grade products. Use of liners helps to keep the contents safe for the entire duration.

- When transporting fine powders Liners are a must uses when shipping fine powdery material. while it is being loaded and maneuvered Such material is likely to sift out of the seams and the body of the FIBC. therefore, there is a risk of product loss. FIBC liners come useful in such situations. FIBC Liner keep the chemicals or powders inside during the entire process of transportation.

Comments

Post a Comment